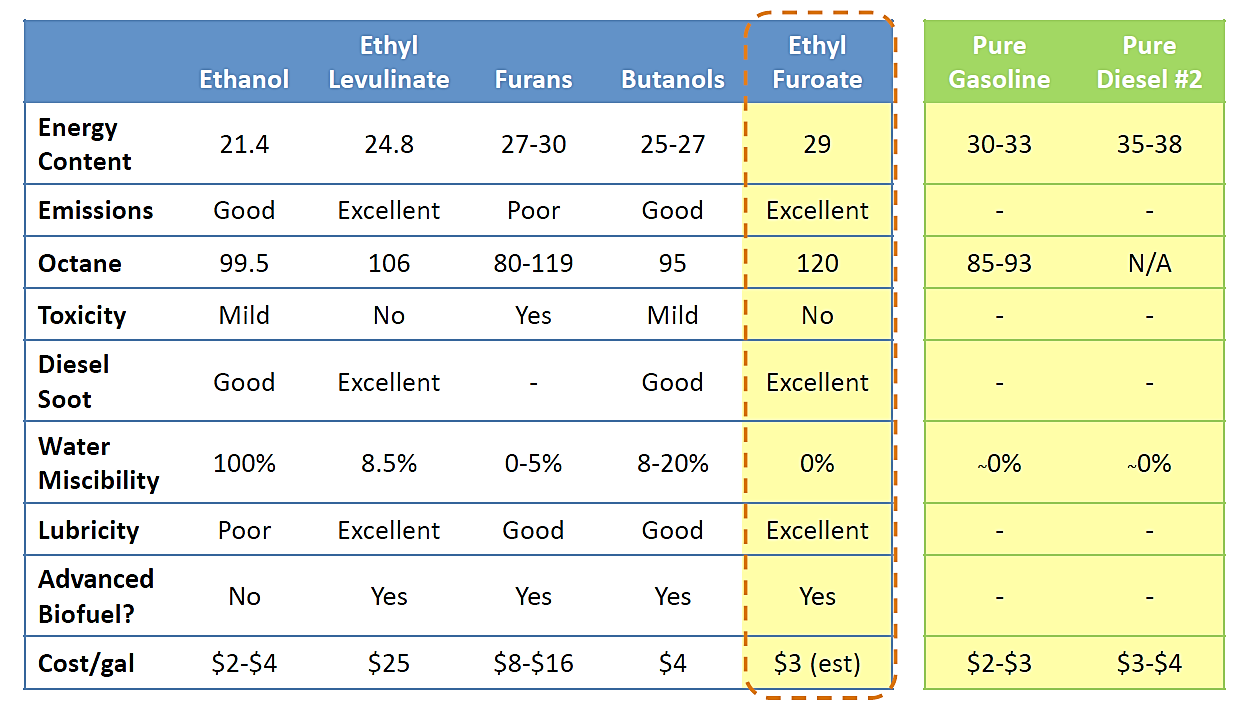

The flagship product of our portfolio is the Ethyl Furoate (EF) molecule invented by Dr. Pete Mikochik, and developed by Aviad Cahana and Trever Skilnick at the facilities in Albuquerque, NM. The novel molecule is created through the homogeneous catalysis reaction of 5-(chloromethyl)-2-furfural (CMF) and Ethanol.

The resulting molecule (seen here to the right) is an excellent

fuel oxygenate that obtains a high oxygen content to mass ratio-

key to creating a potent oxygenate.

Ethyl Furoate (EF) - C8H10O3

The xFuroate technology uses the alcohol during the catalysis step- but the resulting molecule does not retain the negaitve qualities of the alcohol. In simple terms, the alcohol is "upgraded" to an xFuroate.

Along with the high energy content, the ability to mix completely with gasoline, allows EF to be blended at much higher percentages than conventional ethanol or cellulosic ethanol without penalty. Ethyl Furoate (EF) enables the ethanol "blend wall" to be extended, surpassing E15 and E20 gasoline blend quantities.

The xFuroate technology creates a bio-derived advanced biofuel that allows ethanol to achieve its mandate of increased production of domestically-sourced fuels, achieve energy independence and create a sustainable future.

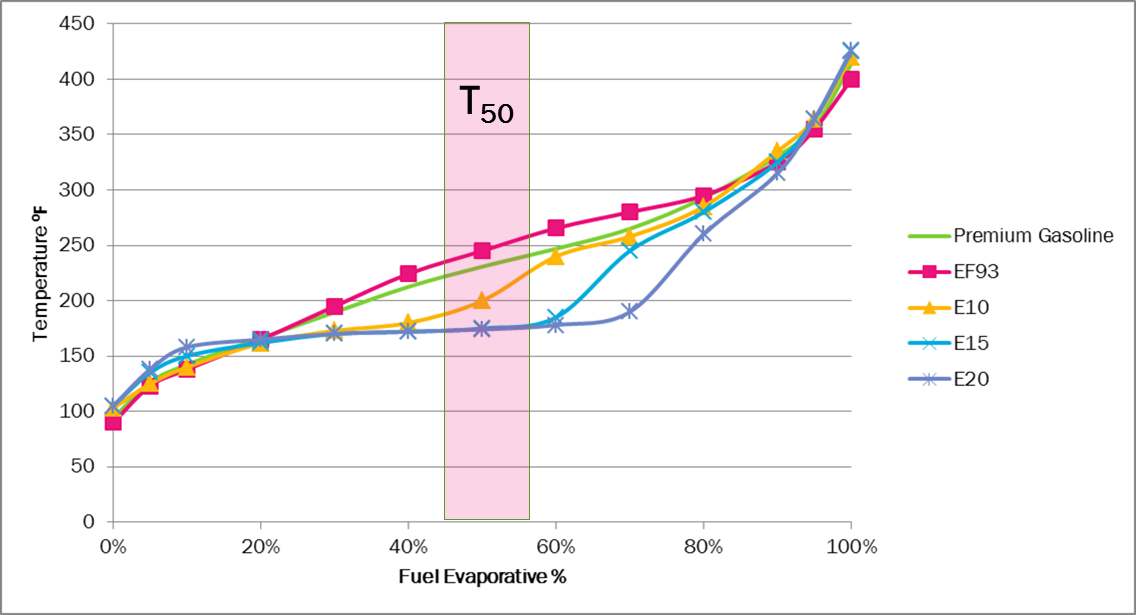

Experts* have highlighted the T50 distillation point

as critical to engine efficiency, driveability, engine warm-up and

power production. Fuel with a low distillation temperature can

exhibit problems with cold starting and vapour lock as

well.

In a 100-page petition to the EPA, DaimlerChrysler, Ford, General Motors and 28 manufacturers represented by the Association of International Automobile Manufacturers (AIAM), claiming restrictions on distillation T50 to 170oF minimum, will reduce exhaust emissions in a cost- effective manner. Automakers project that controlling distillation parameters will reduce hydrocarbon emissions by 15% and (CO) emissions by 19%.

Looking at the relative performance of EF93 versus available gasoline fuel blends at the pump, one can see the phenomenon exhibited by higher blends of ethanol in gasoline- dipping significantly through T50, while EF93 trends with the base test fuel.

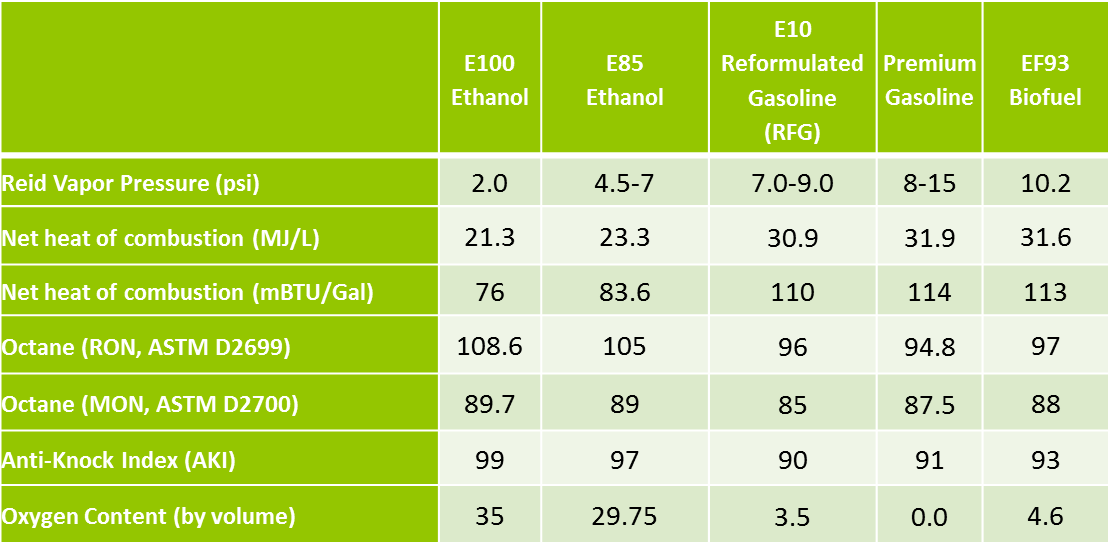

Testing of a blend of Ethyl

Furoate (EF) and gasoline to produce a consumer premium grade

93-octane advanced biofuel (EF93) demonstrated superior properties

that increase engine performance and raise fuel efficiency.

Due to EF's higher oxygen content, emissions can be reduced further

than standard pump gas, E10 (10% ethanol blend). EF93 also

exhibited a superior Reid Vapor Pressure (RVP) keeping evaporative

emissions aligned to non-oxygenated gasoline.

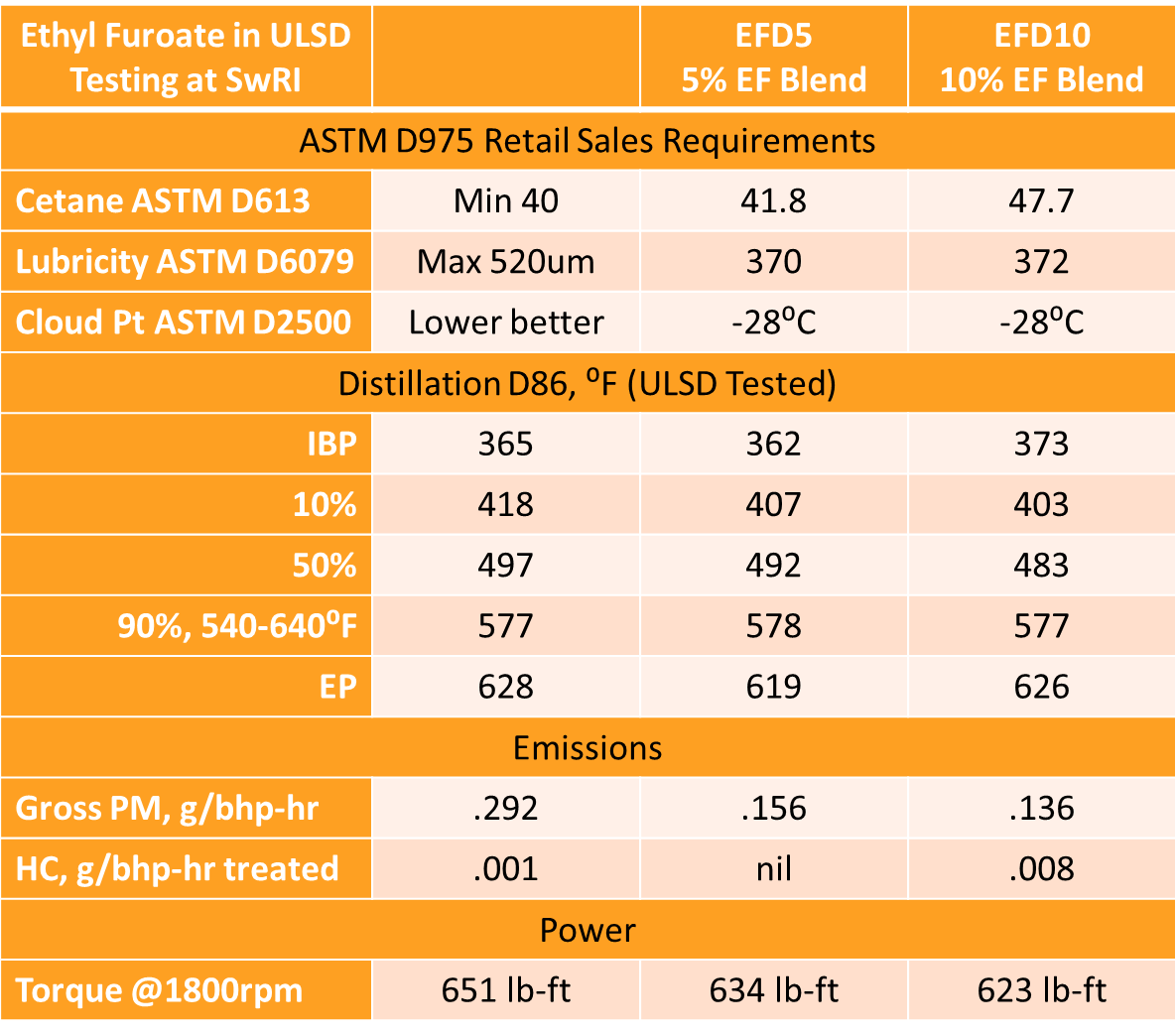

In June 2013, Ethyl Furoate (EF) was extensively tested at Southwest Reasearch Institute (SwRI) as a cellulosic fuel additive in consumer Diesel fuel. The xFuroate was tested at both 5% and 10% blends in Diesel- creating two new advanced biofuels, EFD5 and EFD10 respectively.

The xFuroate advanced biofuel blends were rigorously tested against the ASTM D975 standard (required to pass for sale to consumers at retail stations) and for power, emissions & fuel efficiency in a medium duty Ford diesel engine. The engine tests were performed according to U.S. Code of Federal Regulations (CFR) Title 40 Part 86 Subpart N requirements.

When the final testing results came in, the two xFuroate advanced biofuel blends, EFD5 and EFD10 had passed both the ASTM D975 requirement, and the emissions testing. Both had a significant reduction in gross Diesel soot emissions (particulate matter), demonstating the xFuroate fuel additive technology as a viable alternative to increase health and safety around engines with non-filtered Diesel exhaust.

The Diesel particulate matter (DPM) reduction will also allow automobile manufacturers to reduce the Diesel Particulate Filter (DPF) regeneration frequency, increasing real world fuel efficiency and significantly reduce "uncontrolled" gross emission events when raw fuel is burned in the exhaust system to clean the DPF.

A selection of the results are shown in the chart to the right.

While further testing is progressing, the performance demonstrated

by Ethyl Furoate (EF) as a oxygenate in Diesel is a significant

step to a low emission oxygenated Diesel biofuel.

The xFuroate technology is revolutionizing the world of fuels with a novel bio-derived oxygenate additive with superior performance characteristics.

Our patented chemical processes produce a family of novel molecules that cost-effectively convert cellulosic biomass and alcohols (especially ethanol) into commercially viable fuel additives. These fuel additives can be blended into gasoline, diesel or other biofuels to achieve desired behaviours and performance.

We are rapidly scaling our production facilities and seeking financial and strategic partners to bring the promise of high performance oxygenates to the gasoline and diesel markets.

- Ethyl Furoate (EF) extends the ethanol "blend wall" while improving performance and fuel efficiency

- Combining ethanol and xF technology to create an oxygenated-diesel for PM reduction

©2013 xF Technologies Inc, all

rights reserved