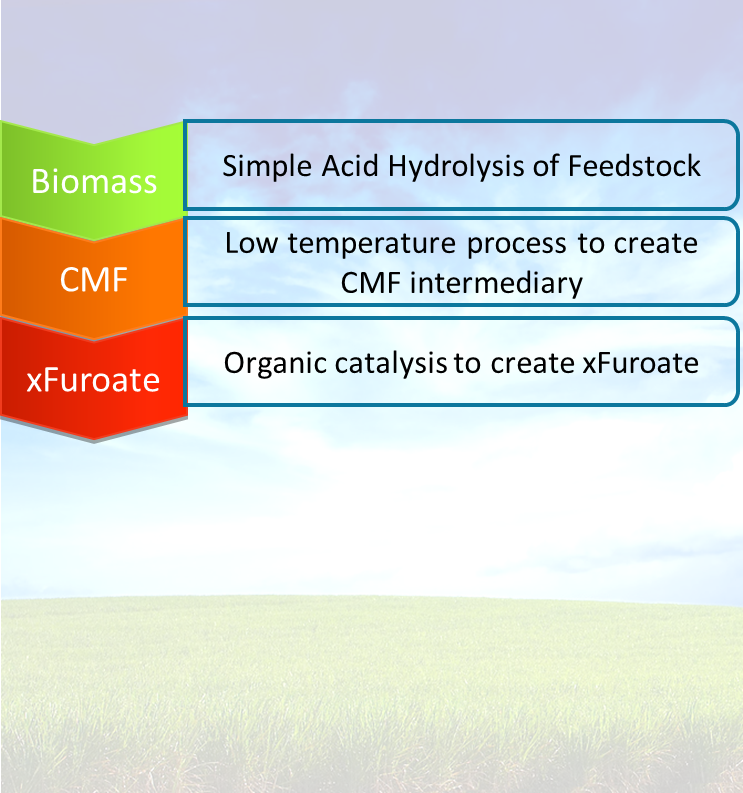

We have developed a patented (USPT#US2011/048009, PCT 2012/024353) chemical, 2-step process that converts biomass-derived C6 sugars into an oxygenated additive to gasoline and diesel. The xFuroate process is a game-changing technology that creats bio-derived fuel additives with superior properties at market competitive prices, enabling a green way of doing business.

The xFuroate process is designed to be agnostic to the type of biomass feedstock used, therefor any biomass source that is high in cellulouse and other sugars that contain 6 carbons (hence “C6 sugars”) are a viable options. Corn stover, agricultural waste and begas are all suitable feedstocks.

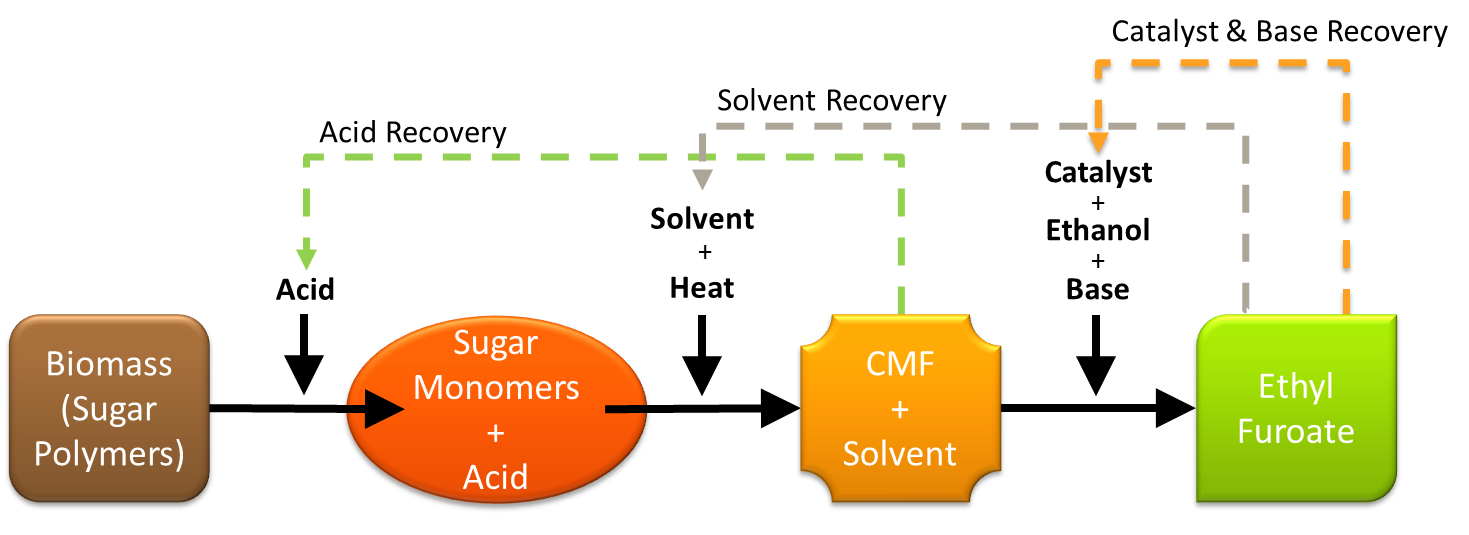

The hydrolysis of different types of biomass to sugars is known, and is typically done using a form of mineral acid. One major problem, typically, is the separation of the sugars from the acid, which is expensive, etc. A key advantage of the first step in the xFuroate process is that the separation of acid and sugars is not required as the feedstock to the xFuroate process is the acidic syrup. This significantly reduces operating cost and complexity.

The feedstocks and processing of the biomass are available from

a wide selection of partners and can be directly feed to the

xFuroate process.

The xFuroate process is low-energy input and high yield.

The process inciporates several layers of recover and recycling to

keep a very small environmental footprint. The xFuroate

process is modular, scalable and capable of co-locating to

exisiting feedstock locations or alcohol processing

plants.

Biomass-derived C6 sugars are converted to an intermediary, 5-(chloromethyl)-2-furfural (CMF), through a patent pending process.

The syrup is then fed to front end of Incitor system and, via the patent-pending process, is converted into CMF. At this point, the resulting CMF is separated from the acidic media by using a standard solvent. The CMF intermediary mixture is then fed to the second step.

The mixture of CMF and solvent from the first step is mixed with an alcohol, typically Ethanol. A novel organic homogeneous catalysis process in undertaken to create the xFuroate molecule. The pH of the mixture is kept at around neutral. The products of this reaction are named after the alcohol used (x) and the chemical structure it is attached to (Furoate). Examples include Ethyl Furoate (EF), Methyl Furoate (MF) and Decyl Furoate (DF).

The xFuroate technology is revolutionizing the world of fuels with a novel bio-derived oxygenate additive with superior performance characteristics.

Our patented chemical processes produce a family of novel molecules that cost-effectively convert cellulosic biomass and alcohols (especially ethanol) into commercially viable fuel additives. These fuel additives can be blended into gasoline, diesel or other biofuels to achieve desired behaviours and performance.

We are rapidly scaling our production facilities and seeking financial and strategic partners to bring the promise of high performance oxygenates to the gasoline and diesel markets.

- Ethyl Furoate (EF) extends the ethanol "blend wall" while improving performance and fuel efficiency

- Combining ethanol and xF technology to create an oxygenated-diesel for PM reduction

©2013 xF Technologies Inc, all

rights reserved